- March 31, 2017

Delivering Your Body Warmth

Interaction, as in holistic experience, can take a variety of forms ranging from physical to emotional side. As in multimodality in interaction, some human touches such as stroking and rubbing create warm and intimate connection, delivering your body warmth to the counter party. Playing with this tactile experience and warmth as in temperature, my goal in this project was to blend tactility and temperature sense to connect the user with an object with a subtle and poetic approach.

Starting with brainstorming at an early phase, I set up the following key values.

Low-Fidelity Prototyping

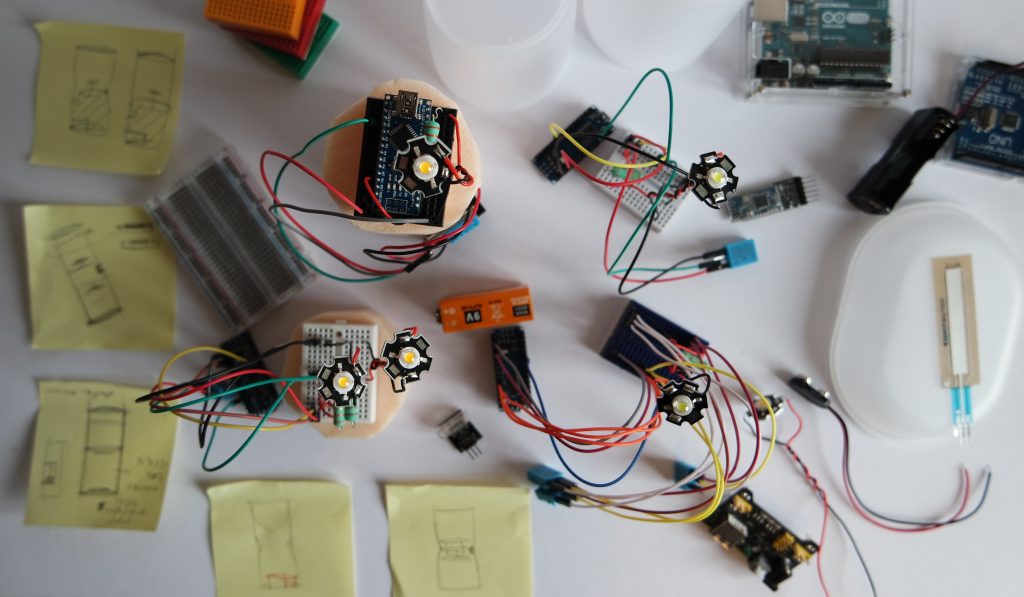

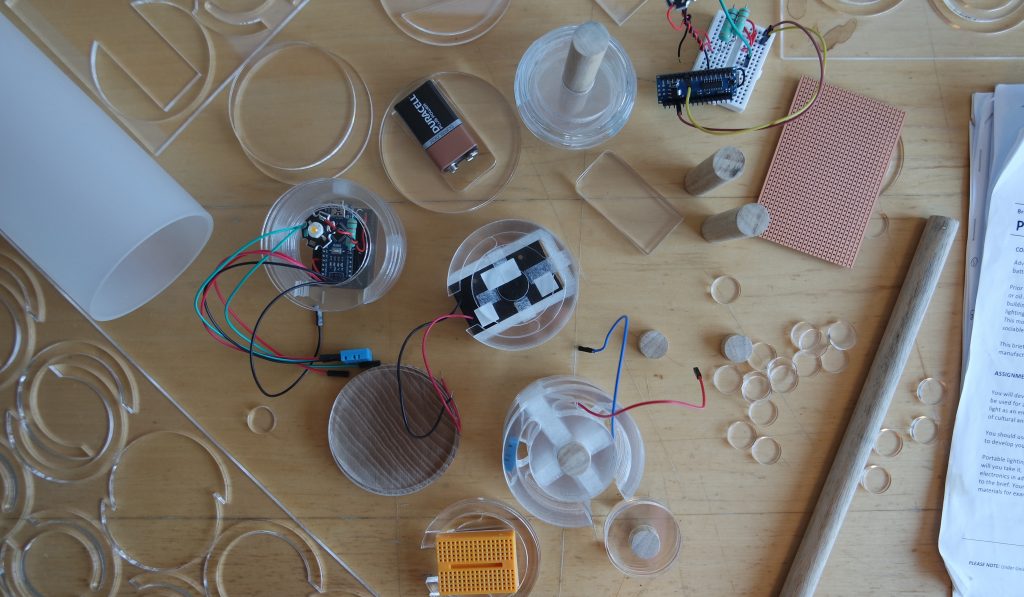

To quickly test feasibility of my initial approach, I started tinkering with hardware (open source), sensors, actuators, wires, and mounting features for its enclosure design (mechanical parts). Designing structural layout for internal architecture whilst considering usability & robustness for product demo, rework, and assembly has played an important role in its overall build.

Programming Interactivity

As part of my initial rapid prototyping (Lo-fi) process, I’ve also iterated electronic circuits to review the interaction. Sensing area (location), physical volume, LED performance (brightness & energy efficiency), portability, etc have been major areas of focus at the early phase. For example, to verify ‘product – use case fit’, I have tested if LEDs are bright enough to fit their targeted use case (room dimensions, spatial needs, environment, device location, etc). In terms of portability side, charging, form factor, and weight are the key usability concerns.

Mid-Fidelity Prototyping

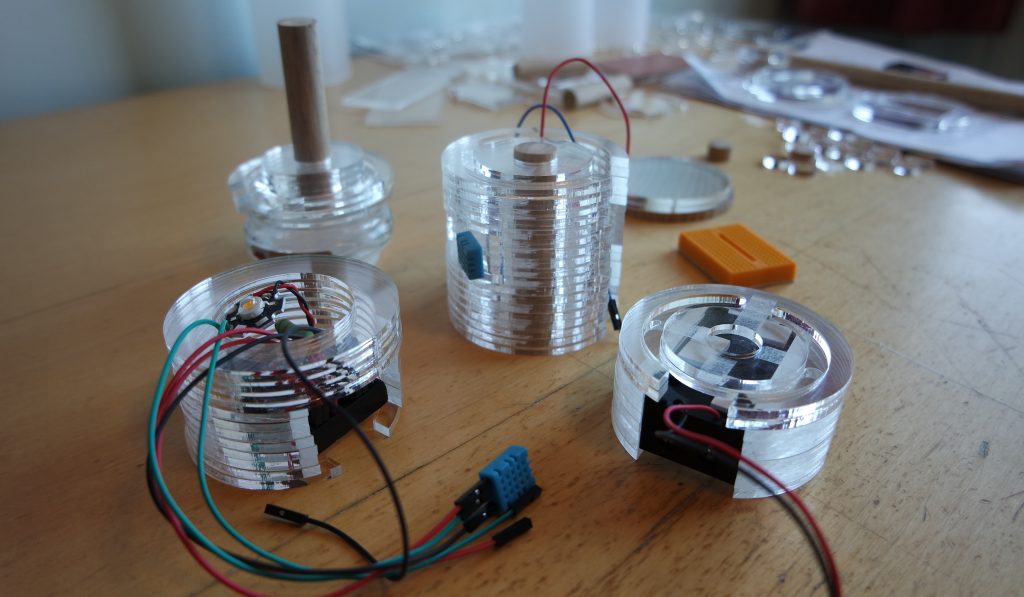

Considering this phase to be an opportunity where I can verify final interaction concept in system operating together with physical models with mid fidelity. To test its interactivity without any distracting physical elements, I have created a generic cylindrical shape as a starter with a layered manufacturing approach. This has allowed me to create spaces; layer by layer as in a modular system to let wires can pass through for the purpose of assembly and rework.

Admittedly, being able to rework in the context of assembly has been one of the key drivers that has determined its form factor, in addition to its usability and aesthetics. Plus, securing structural robustness for product demo (demonstration) has also been an important part.

Material Science

*Felt is capable of amplifying the warmth (created by gentle friction such as stroking/rubbing) by its unique properties that makes it a perfect enclosure material.

When tactility meets temperature sense as in multimodal interaction, it creates unique haptic experience that triggers user’s connection with an object. Testing out a variety of soft materials such as sillicon, TPU, cotton fabrics, etc for its enclosure material (covering the sensing area), I reached to the conclusion that *felt, as in fiber polymer, is by far the most efficient in thermal conductivity (frictional). It is capable of amplifying the warmth (created by gentle friction such as stroking/rubbing) by its unique material properties and attributes which makes it a perfect enclosure material.

Vimeo Link 01 Material Use Demo (*Felt)

Vimeo Link 02 Interaction Prototype Demo

Introducing ‘LINK’

Powered by gentle human touch and body warmth, ‘LINK’ will create intimate connection with you. It is a portable lighting (bedside) with a subtle and poetic approach in interaction. Default mode (bedside timer) is designed to facilitate better sleep; it will steadily grow dim and eventually go off as it passes designated time that you set up for yourself. ‘LINK’ operates with unique interaction as it is fundamentally powered by your gentle human touch and body warmth with a hint of soft tactility.

Design for Manufacturing (DFM) : To productize the concept, I set the location of sensing area in accordance with it’s intended user scenario. Charging can be made through Micro USB; it lasts ideally more than 7 days for 3 hours of charge depending on use case. Due to its complexity of internal architecture, I have left spaces for each acrylic layer (Room for Wiring) for prototypes to prevent malfunction. Thanks to its generic form factor, processing materials as in manufacturing side can be simple and efficient.